Hydro Dipping Process (Water Transfer Printing)

1. Surface Preparation -

The part (metal, plastic, or other material) is cleaned, sanded, and primed to ensure the design sticks properly.

2. Base Coat Application -

A specific base color is applied depending on the final look you want. This helps enhance the pattern's visibility and effect.

3. Film Placement -

A printed hydrographic film (with the design/pattern) is carefully laid on the surface of water in a dipping tank.

4. Activation -

A chemical activator is sprayed on the film, dissolving it into a floating ink layer that can now adhere to surfaces.

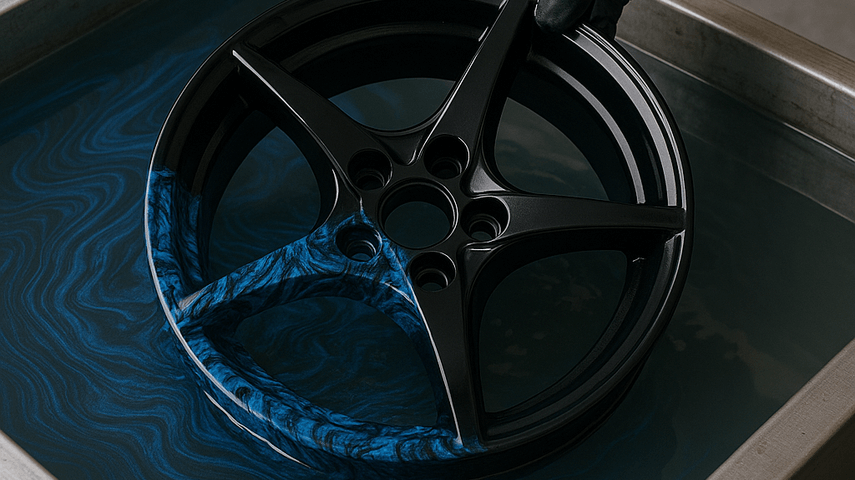

5. Dipping the Part -

The part is slowly and precisely dipped into the water. The ink wraps around it evenly, transferring the design onto the surface.

6. Rinsing -

The dipped part is gently washed to remove any leftover film residue without affecting the design.

7. Drying -

The part is thoroughly dried before the final stage.

8. Clear Coat Finishing -

A protective clear coat (glossy, matte, or satin) is applied to seal the design and add durability and shine.